How to create a Bill of Material for an EMS

The bill of materials is comparable to the list of products and purchases that kitchens need to prepare meals. It also allows the chef to estimate the cost of preparing a meal and eliminates the likelihood of skipping a vital stage or ingredient. A BOM plays a very similar function in the case of a partnership between a producer and an EMS contractor. In the following article, you will find out what is in this list and how should you prepare it correctly?

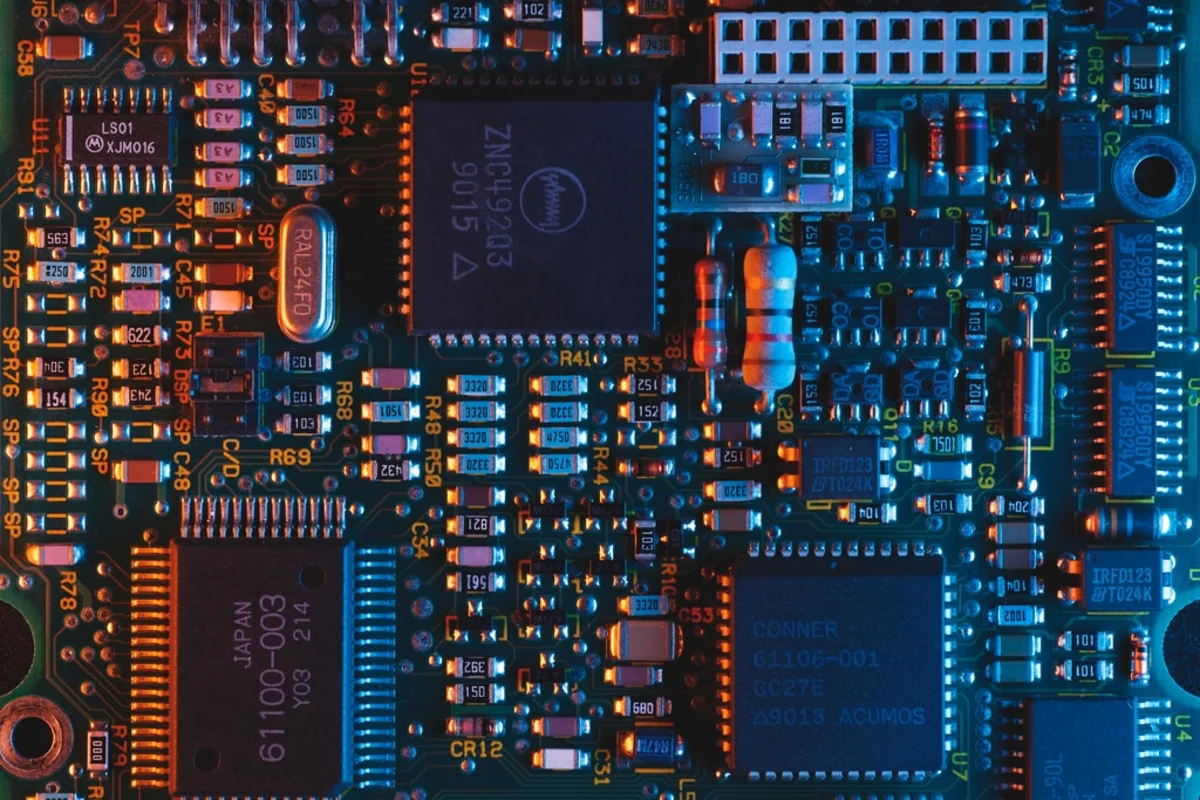

Bill of Material is a comprehensive list of elements, raw materials, subassemblies, parts, and the quantity of each needed to produce the final product. In addition, it contains information on virtually all its details, from a simple screw, through electronic components, to the packaging components. Briefly, BOM is a list of elements (purchases) necessary to create a product. It collects all kinds of information and is used by various people involved in implementing the project, including designers, engineers, controllers, and subcontractors.

In most cases, the correct development of the Bill of Material determines the success or failure of the entire production process. Therefore, it is imperative in the EMS industry, characterized by great detail and complexity and requires excellent logistics and warehousing management.

What is a BOM for in practice?

You may be wondering why Bill of Material should be appropriately prepared, and a freely compiled list of elements is not enough. Well, this is because the BOM is not just a shopping list. BOM plays a leading role in project management. It allows you to list all the parts needed to manufacture a product, manage delivery schedules suppliers, and obtain the cost of the final product. Moreover, a bill of materials is often linked to a production order. Thanks to the BOM, it is possible to reserve ingredients in the warehouse to avoid downtime caused by their subsequent lack. In addition, EMS, which operates based on a BOM, can also book elements for the future that are currently not in stock.

If you outsource production, it is crucial to create an accurate, rigorously vetted, and up-to-date BOM each time it is passed on to the manufacturer or supplier; otherwise, you can expect delivery delays.

Also Read: Microsoft ready to buy Activision Blizzard for $68.7 billion

How to make a BOM for an EMS

A good BOM for an EMS is primarily a one and complete BOM. That’s a standard feature for all industries. The best solution is to implement it in the form of a spreadsheet, thanks to which it will be possible to analyze it from many angles and obtain an overview of the entire project. The BOM should be order and quantity-oriented and should be in a tree structure that allows you to envision the project through subsets.

Maintaining a particular naming scheme is essential when creating a BOM in a tree structure. If you use several different names in a bill of material for a part, duplicates may arise in various subassemblies, hindering the statement’s practical use.

What should the BOM for an EMS include?

As it has already been presented, the bill of material combines all the elements necessary to produce a product in one document. Each component, subassembly, and the raw material is identified by a standard product code (generic coding, not project-specific), and each product variant must be identified with a specific, unique product code. In the BOM, each element you should describe as precisely as possible. It is essential to take into account several segments.

- Specification: unambiguous identification of the element, indicating its storage conditions and the maximum possible storage time.

- The number of components: The BOM should indicate a quantitative statement of the items required to produce one piece of the finished product. If an element is present at different stages of production, it should be included in the BOM separately at each level of the process, as required.

- Alternate Parts List: this list suggests elements with which EMS can replace the original components as needed. It is also good to indicate what similar or identical features have alternatives compared to the original ones. By pointing to alternative parts, you minimize the risk that potential problems with the availability of components will disrupt the entire production process.

- AVL (approved vendor list): is a list of manufacturers the client has approved to deliver materials specified in the BOM.

- Reference designator (RefDes): unequivocally represents the installation place of the detail on the circuit board (PCB).

Not only the specification of the components

The specification of the components alone is not enough for the bill of material to be complete. You should also include a list of steps to be followed in your EMS listing if the BOM is for a box-build or electro-mechanical assembly production and a product creation manual. You can create the document in CAD or attach it as a separate PDF file. The form is optional.

When creating the BOM, include the MPN, i.e., Manufacturer Part Number, for each item. Thanks to it, it will be possible to identify the material unequivocally. The absence or specification of an incomplete MPN may give the EMS room for interpretation, which may not necessarily be accurate.

Remember about updates

In practice, the BOM is modified many times during the production process. Therefore, if you would like to ensure that EMS follows these iterations and is up-to-date, it is necessary to provide a contractual updated version of the statement after each change is made. Thanks to this, you will be sure that the entire production process, despite the modifications, will run smoothly and will not require additional costs on your part.

The bill of materials is undoubtedly a great tool in the hands of an engineer or designer and an essential tool for communication with your contractors. Moreover, BOM also guarantees the success of the entire project, which is production, so it is crucial that you allocate the right amount of time to its development and prepare it as thoroughly as possible.

Here you can find more information about electronics manufacturing services: https://asselems.com/