How to Prevent Chemical Hazards in the Workplace

If you want to prevent chemical hazards in the workplace, you have to be aware of OSHA’s Hazard Communication Standard. This article will explain the process of identifying and managing hazardous chemicals. In addition to the hazard identification process, the workplace hazardous chemical management process involves the assessment of risks. It includes comprehensive onsite inspections of the workplace to identify hazardous chemicals and their associated situations.

Substitution helps prevent chemical hazards in the workplace

Substitution is a process that involves replacing dangerous chemicals with less hazardous ones. It is a top control measure that is mandatory under law. It has been established by the Directive 89/391/EEC and is reinforced by the Regulation No 1907/2006 (REACH). Substitution can take several forms, including technical measures, organisational measures, and product revision.

The first step is identifying toxic chemicals used by the company. It can then begin to investigate the most suitable alternatives. It can be a challenging process, and may require the company to make changes to their processes and products. They must also inform their customers, suppliers, and subcontractors of these changes. Substitution can also be an effective solution for preventing chemical hazards in the workplace.

Substitution should be implemented with a multidisciplinary team, which includes preventive services, occupational physicians, technical personnel, and workers’ representatives. It should be incorporated into the company’s general policy, and take into account existing knowledge and relationships with external stakeholders. Ideally, it should be a part of a company’s preventive culture, which can help identify hazards earlier and gain broader support from stakeholders.

Substitution can help prevent chemical hazards in the workplace by replacing a hazardous chemical with a safer one. In some cases, it may be possible to take the same sample somewhere else in the plant. In addition, it can help to change the way people think about chemicals in the workplace.

OSHA’s Hazard Communication Standard

OSHA’s Hazard Communication Standard is designed to provide workers with information about hazardous chemicals. The Standard covers both health and physical hazards, and it requires employers to disclose hazardous chemicals to their workers. The standard also requires employers to train their employees about the hazards and how to handle them.

For the workplace, this means having a written plan for chemical hazards. This plan is only required if the work involves handling of hazardous chemicals. Workplaces without chemical hazards are not required to have a written program. The written program should detail all activities performed by employees, list chemicals present on the site, identify responsible parties, and specify where written materials are available. The written program should also include a hazard assessment for each chemical.

Chemical labels must be written in easy-to-understand language, so that workers can understand what they’re handling. It’s important to give employees information about chemicals when they’re first assigned to a job. The information can include the name of the chemical, the manufacturer’s code number, or the batch number.

OSHA’s Hazard Communication Standard is designed to educate employers about the dangers associated with certain chemicals. This information is vital for employees to protect themselves from chemical exposures. The standard also requires employers to train their workers on how to read and use safety data sheets.

The Hazard Communication Standard is a new rule that requires companies to update safety data sheets and labels. Workers must receive training on the new format and elements of the label. Chemical users and producers must also update their safety data sheets. Further, the new standard requires producers to review and classify all of their chemicals according to the new classification criteria.

Implementation of the Hazard Communication Standard (HCS) will reduce injuries and illnesses associated with chemicals. By educating employees about chemical hazards and the safest way to use them, OSHA can improve health outcomes. Proper implementation of the HCS will help employers design a protective program appropriate for the risks and needs of their employees. Once employees understand the hazards of chemicals, they will be more likely to participate in protective programs and take action to protect themselves.

The Hazard Communication Standard requires employers to identify chemical hazards in the workplace and create safety communications. These safety plans must meet OSHA’s requirements for chemical safety. Hazard communication must also include warning labels. Labels must contain the name of the chemical, the manufacturer, and the batch number. OSHA requires these labels to be clearly legible and contain warnings in English.

Hazard communication must be a continuous program within the facility. A successful Hazard Communication program will protect employees and pass inspections. It should include specific accountability for the initial activities and ongoing activities.

Occupational exposure to toxic substances

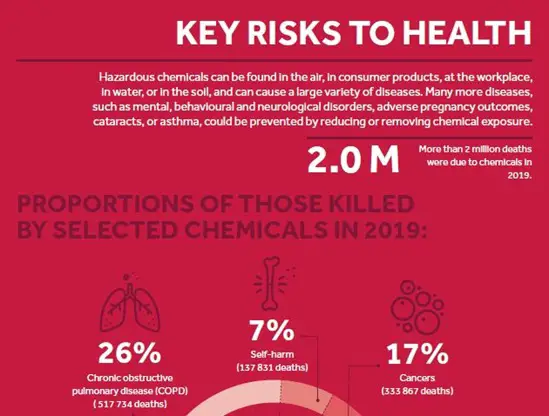

Occupational exposure to toxic substances is one of the leading causes of illness in the workplace. Regulations have been put in place to protect workers and the public from the hazards of toxic chemicals. Depending on the chemical, workers can experience irritation, sensitization, and carcinogenic effects. Exposure can also lead to fires and explosions. It is therefore essential to ensure that workers are aware of the risks of exposure to chemicals.

The United Nations (UN) has set out principles for protecting workers from occupational exposure to toxic substances. These principles include the responsibility of employers and governments to minimize exposure, the importance of providing information to workers, and effective remedies for violations. These principles are based on information collected through site visits and from industry and labor organizations.

Dose-response assessment is the process of assessing health risks associated with occupational exposures. It involves the use of mathematical models to extrapolate the data obtained from animals and humans to determine the potential health risks of occupational exposures. The goal of this process is to characterize health risks for a wide range of occupational exposures.

Exposure to toxic substances can result from exposure to a wide variety of materials and processes. For example, some workers may be exposed to fiberglass, which is used as a filler for epoxy resins, electrical insulation, and printed circuit boards. This material may cause skin irritation, fatigue, and a variety of other health effects. These health effects depend on the substance, the amount of exposure, the duration of exposure, and the way the substance enters the body. Exposure to polychlorinated biphenyls, which are widely used in electronics, can result in respiratory issues, reproductive problems, and cancer.

A comprehensive medical surveillance program is an essential element of any workplace safety plan. It should include baseline and follow-up examinations of all workers. It should also include detailed medical histories and information about hazardous substances. The results of these examinations will serve as a basis for assessing the effects of work operations and hazardous substances.

Occupational exposure to toxic substances has devastating consequences. Some workers may experience adverse effects immediately, while others may not develop symptoms until years or decades later. Because toxic exposure cases are not as easily identifiable as car accidents, they require extra care and expertise on the part of lawyers. These cases require specialized knowledge and experience to prove causation.

As a result of occupational exposure to toxic substances, employers are required to provide adequate medical care for their employees. The employer must also provide follow-up examinations for employees. Further, employers must provide safety data sheets for hazardous chemicals, and ensure that employees can access them. Ultimately, it is important to protect employees from occupational exposure to toxic substances by preventing the spread of the chemicals.