How Vibration Analysis Is Used To Detect Faulty Equipment

This article aims to give you some insight into how vibration analysis is used to detect faulty equipment. There is a lot of information packed in this one article and it’s worth diving into if you’re looking for ways to make sure your manufacturing process is accurate and that your company gets what they need.

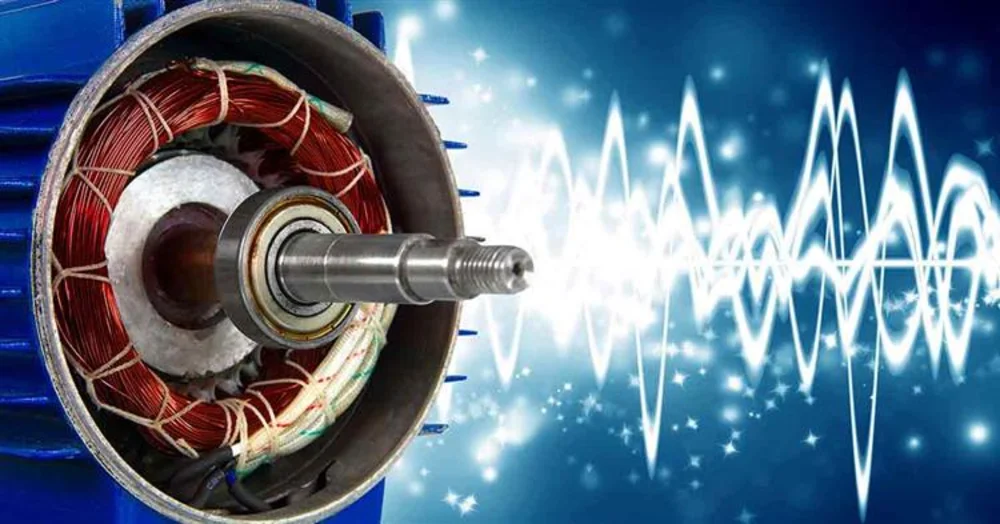

Have you ever noticed humming or vibrations coming from your electronics, or equipment in your laboratory? Vibration analysis is a process that monitors vibration levels and investigates the patterns in vibration signals. It is commonly conducted both on the time waveforms of the vibration signal directly, as well as on the transients of power waves. Consider this article for a review on this topic with breakdown of pros and cons.

How Does Vibration Analysis Work?

Vibration analysis is a process used to identify the cause of vibration in equipment. With modern technology, it is possible to detect faults before they cause any damage. This process begins by measuring the vibration of an object using a device called a vibrometer. Once the vibration is known, the analyst can use this information to determine which part of the equipment is causing the problem. By identifying and solving the issue early on, it prevents major damage from happening.

Uses of Vibration Analysis

Vibration analysis is a technique that is used to detect faulty equipment. When an equipment is running, it creates vibration. This vibration can be detected and analyzed in order to find the source of the problem. Using wireless vibration analysis, technicians can easily determine if there are any issues with the equipment and make necessary repairs or adjustments.

The use of vibration analysis to detect faulty equipment is becoming more and more common. Not only is it a reliable way to detect problems, but it can also help limit the amount of damage that occurs when something goes wrong. By understanding how vibration analysis works, you can use it to your advantage when investigating potential issues with your equipment.

Vibration analysis typically uses three types of data to assess a system: motion, frequency, and amplitude.motion data shows how the system moves over time, while frequency data shows how often the system vibrates at certain intervals. Amplitude data tells you how strong the vibrations are overall.

By analyzing these types of data, you can quickly identify problems with your equipment. For example, if your motion data shows that the system is moving in an abnormal fashion, this could be a sign that there is a problem with the gearshift linkage or belt tensioner. Meanwhile, abnormalities in frequency or amplitude signals could indicate issues with motors or bearings. In either case, resolving these issues would likely prevent much damage from occurring.

Benefits of Vibration Analysis

Vibration analysis is a process used to identify and locate the sources of vibration in an industrial or mechanical system. By understanding where the vibration is coming from, it can be more easily identified and corrected. There are many benefits to using vibration analysis in your business:

Reduced downtime: By quickly locating and correcting the source of vibration, you can save yourself time and money.

Improved equipment efficiency: Improved equipment performance can be attributed to reduced noise levels, less stress on components, and quicker repair times.

Reassured customers: Knowing that your equipment is operating safely and efficiently helps reassure customers.

Faulty component detection: Vibration analysis can also help detect faulty components in machines, which can save you money and hassle down the road.

Implementation of Sensor Equipment and Procedure for Monitoring Equipment

Monitoring equipment for vibrations can be critical to detecting faulty equipment. By implementing vibration analysis, faults can be quickly and easily identified. The procedure for monitoring equipment with vibration analysis is as follows:

1) Choose the type of monitoring equipment to be used. This will depend on the type of fault that needs to be detected.

2) Measure the vibrations of the monitored equipment at various frequencies and amplitudes.

3) Compare the measured vibrations with those expected based on design parameters and operating conditions.

4) If there are any discrepancies, investigate the cause and take appropriate action.