Smart Linear Motion and Actuation Solutions

The application of linear actuators is not connected only to industrial areas or some complicated technical operations. Now it’s what we use almost every day even without understanding it. These simple devices make movements simpler and quicker, at the same time substitute human efforts application. Just press the button and get what you need.

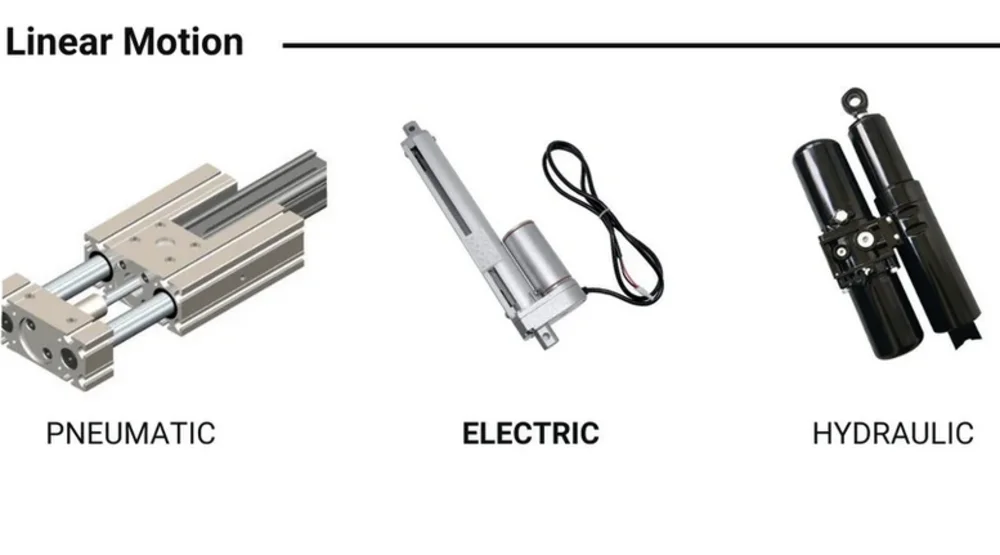

Under the concept of an actuator, a mechanism is hidden, the main task of which is to transfer forces from the control device to the actuator. They differ from each other in the way they transfer energy.

You may ask, where do we actually use it? Home automation is a bright example of linear motion actuator use. For example, you can incorporate an electric linear actuator into your furniture in the kitchen. It will allow you to hide many unnecessary or rarely used things inside of a hidden compartment. Make your kitchen look modern and uncluttered this way! By pressing the button, you can get what you need immediately.

If we consider household and building electromechanics, one of the most popular actuators is the drive of gates and gates. In simple words, this device is called the door actuator. It allows the automatic movement of small doors or massive steel gates.

That is just one example of common implementation. There are many other popular cases like:

- Automated windows

- Special smart shades for your windows

- TV lifts of four types

- Automated computer desks

- Smart bed frames

- Hidden kitchen table

- Automated doors for your cat

- Motorized gates, etc.

Having linear actuators of a required type, you can implement any DTY project at home and simplify your regular actions in the way you need it.

What is Actually a Linear Actuator and How Does It Work?

A linear actuator, as the name implies, converts mechanical energy into linear movement. Typically, such mechanisms are used to obtain mechanical energy from electricity. A movable stem is installed in a plastic or metal housing. Cables, plugs, and a variety of connectors are provided for the supply of electricity. The level of consumption depends on the model and design.

There are two main versions of linear actuators: vertical and horizontal. It determines the direction of movement of the rod relative to the motor shaft. Even under extreme conditions, linear sets retain their qualities. In work, they are unpretentious. Their service life is long, the design is simple. To adverse conditions, resistance can be provided with additional protection.

The advantages of linear actuators include:

- the simplicity of design,

- long service life,

- unpretentiousness in work, which allows them to be used even in extreme conditions.

Specific units, depending on the model, may additionally have protection that provides resistance to adverse conditions.

Actuators are produced with different stroke lengths and body sizes, products are also distinguished by linear movement speed and force. The required moving speed and force are achieved by a gearbox installed between the propeller and the motor shaft. To control the operation of the actuator, special devices are used to convert the angle of rotation into a signal and set the required position of the actuator itself.