What is 4D printing? Everything you need to know

What is 4D printing, and have you heard of it? It’s possible that earthquakes or shifting loads could cause the walls of your workplace to stiffen and flex. Wouldn’t it be nice to have water pipes at home that could change their shape depending on the rate of water flow in your home? Alternatively, what if a table came together as you tapped it?

What is 4D printing?

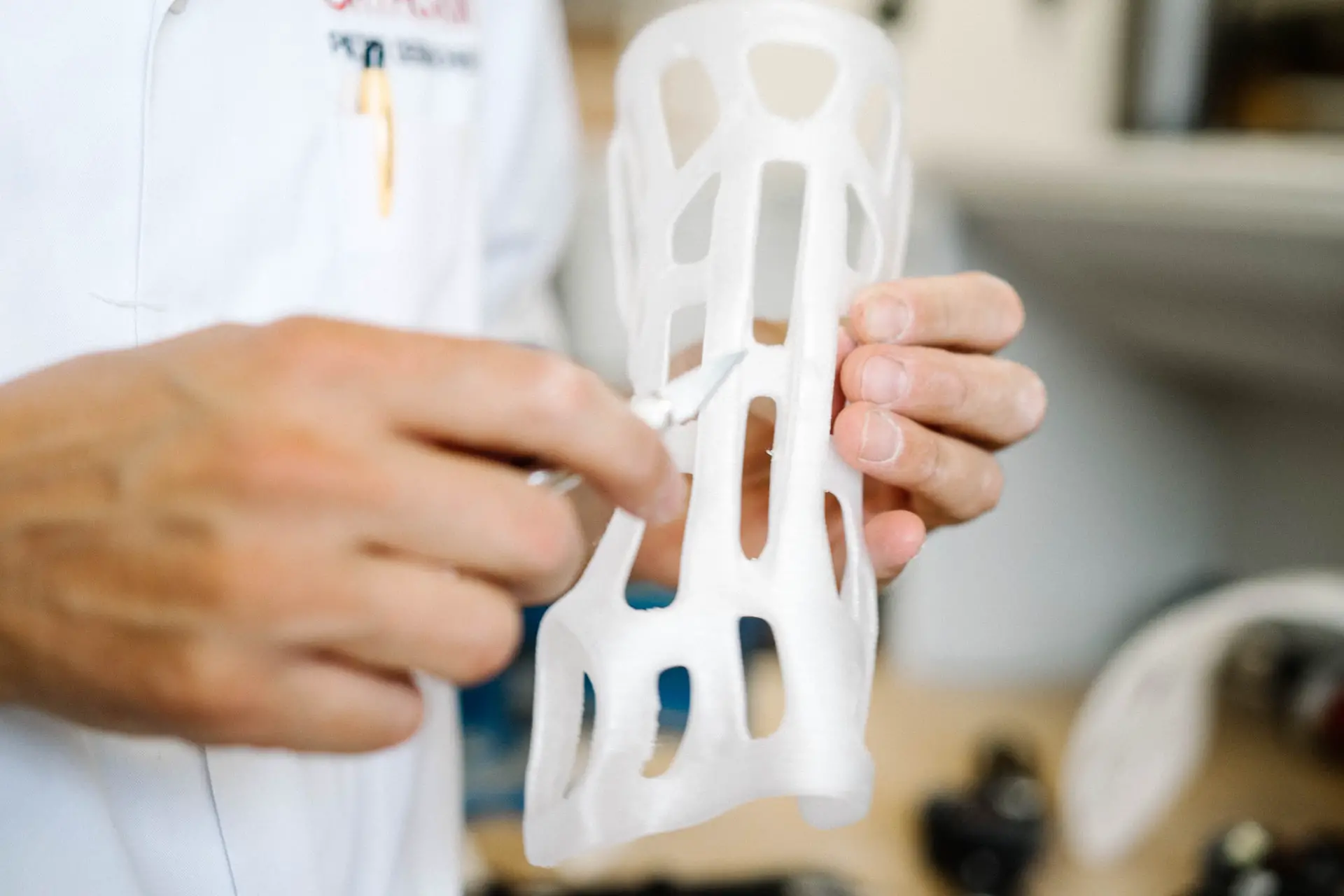

In 4D printing, items that have been 3D printed respond to external environmental stimuli such as heat, wind, water, and other types of energy by transforming into something else. It is possible to design objects that change shape and even their functionality over time using 4D technology.

4D Printing: What Are its uses?

It’s fascinating to see how 4D printing is pushing 3D printing to a whole new level. To stimulate a 3D-printed object to change shape, 4D printing requires unique materials and elaborate designs that can be “programmed.” The aerospace, automotive, biomedical, defence and military industries are just a few of the many potential uses for this technology.

Aerospace

Intelligent materials that respond fast to external stimuli are beneficial in the aerospace sector. Self-deploying structures that can help with ventilation and engine cooling can be developed using 4D printing.

The Self-Assembly Lab at the Massachusetts Institute of Technology (MIT) and Airbus SAS are now working together on a joint project. A 4D-printed material that can be programmed to cool engines when exposed to large temperature variations is being developed by the two organisations at present. To reduce air resistance, they’re looking into air inlet components that can alter shape based on aerodynamic conditions. If this technology is successful, it could aid astronauts on future space journeys.

Read More: How to Start a T-shirt Printing Business | Complete Guide

Automotive

BMW debuted a future concept car in early 2016 that featured 4D-printed car parts that could adapt to various climatic conditions. BMW and MIT’s Self-Assembly Lab recently worked together to build an inflatable 4D structure that can alter the shape in response to variations in air pressure. Car seats that can adapt to the driver’s needs could also be used.

Biomedicine

Regenerative soybean oil has previously been used to generate a 4D-printable and photo-curable resin. Temperature fluctuations cause this biocompatible resin to undergo a shapeshift, which is followed by a restoration to its original shape. Studies on human bone marrow mesenchymal stem cell development have shown that the material can be used. It is hoped that these findings may aid in the development of biomedical scaffolds necessary for the creation of human tissues that function normally.

Several gastrointestinal illnesses could be diagnosed and treated using 4D printing technology. A 3D printing ink packed with magnetic microparticles has been developed by MIT researchers. When these microparticles are injected into the body, they can be remotely controlled to clear blockages, collect tissue samples, or deliver medications to precise injury sites.

Military and Defense

Defence and military applications of 3D printing are becoming commonplace. And it appears that the same holds for 4D printing as well. Engineers are currently working on military uniforms that can be transformed into protective gear against shrapnel or dangerous chemicals through the use of 4D printing. Another possible application is the construction of self-assembling tactical objects such as shelters or bridges.

Conclusion

4D printing has a bright future, especially in the manufacturing sector. Imagine being able to design devices that respond to external stimuli by morphing into something else. Several 4D-printed technologies are still under research, but they will be in use soon enough for the general public to benefit from their use.